COLLEGE CODE

Headlines

AME Department

ABOUT DEPARTMENT

The Department of Automobile Engineering was established in the year 2008 with a mission to prepare highly competent Automobile Engineers for global automotive industries through innovative, industry-oriented curriculum, intensive practical training, and industry exposure to the students in the thrust areas (Automotive Design and Automotive Electronics and Automotive service). The Department focuses on offering industry exposure to the students and train them through Industry projects in the specialized stream of their choice. Major areas of research interest are the Hybrid and Electric Vehicle Technologies, Vehicle Design & Performance optimization and Vehicle Maintenance.

VISION AND MISSION

VISION

- To be a renowned Learning Centre in the field of Automobile Engineering contributing towards development of the society.

MISSION

-

The department indulges in activities to inculcate knowledge, skill and attitude by undertaking activities such as:

- Teaching regular practices and updating new technologies through utilization of software tools and sophisticated teaching aids.

- Guest lectures, workshops, seminars and conferences.

- Bridging the gap between industry and college through frequent industrial visits.

- Carrying out research and development projects.

- Developing entrepreneurial skills through internships and case studies.

STAFF DETAILS

Faculty Name |

SANIVADA USHA KIRAN KUMAR |

Qualification |

M.Tech, Ph.D |

Designation |

ASST PROFESSOR |

Experience |

PEO's ,PSO's & PO's

UG

PROGRAM OUTCOMES (POS)

1. Engineering knowledge: The automobile can be considered to consist of five basic components:

- The Engine or Power Plant: It is source of power.

- The Frame and Chassis: It supports the engine, wheels, body, braking system, steering, etc.

- The transmission which transmits power from the engine to the car wheels.

2. Problem analysis: The next step of the process is to clearly identify what the problem is that must be solved. Sometimes problems can be ambiguous and the team must clearly identify the problem at hand using measurable details when possible. For example, a good problem definition is to eliminate dash board cracking during assembly to zero parts per minute (ppm) vs. a bad example of ‘increase customer satisfaction’. Always be quantitative and avoid ambiguous statements. Clearly identifying the problem focuses the team and stops wasted effort.

3. Design/development of solutions: System controls are in automotive product design and development. When it comes to product design and development, we are committed to helping you ensure that our automotive designs will meet the initial requirements & specifications throughout the automotive product development cycle Integrate quality prior to onset of the manufacturing phase, meet delivery & cost targets, truly recognize and focus on the most critical user inputs, Be optimized to consider the most efficient, effective automotive manufacturing solutions.

PROGRAM EDUCATIONAL OBJECTIVES(PEO)

- PEO 1: To possess knowledge in both fundamental and application aspects of mathematical, scientific, engineering principles to analyze complex engineering problems for meeting the national and international requirements and demonstrating the need for sustainable development.

- PEO 2: To adapt to the modern engineering tools for planning, analysis, design, implementation of analytical data and assess their relevant significance in societal and legal issues necessary in their professional career.

- PEO 3: To exhibit professionalism, ethical attitude, communication, managerial skills, team work and social responsibility in their profession and adapt to current trends by engaging in continuous learning.

THE PROGRAM SPECIFIC OUTCOMES (PSO)

- Mould and develop engineers to serve in industries as professionals or entrepreneur

- Prepare engineers to undertake research and higher learning.

- Design basic automotive systems and make use of advanced automotive systems to improve the performance, safety, maintenance and management of automobiles.

LABORATORIES

Automobile Engineering

The department of Automobile Engineering boasts of four state-of-the-art laboratories to facilitate the young curiosity, to cater the exclusivity of technology and consolidation of fundamentals. The field of automobile engineering is amalgamation of technological advances and fundamental principles. The recent advancements in environmental conservation, the alternative fuel research, the hybrid technologies as well as basic IC engine performance, repair and understanding modules are encompassed.

Two and Three Wheeler’s Lab

With an aim to develop an understanding of latest technological advancements and educate 6th semester students about contemporary technological innovations, the two and three wheeler’s lab is set up in the ground floor of Bhanwar Building. The laboratory comprises of cut sections of various systems used in two and three wheelers, the electric version of two wheeler’s.

Refrigeration and Air Conditioning Lab

The department of Automobile Engineering offers the elective to study the refrigeration and temperature control science. The laboratory comprises of continuous freezer, Ice candy unit, HVAC set up and cooling tower. The laboratory also caters the subjects offered by department of mechanical engineering.

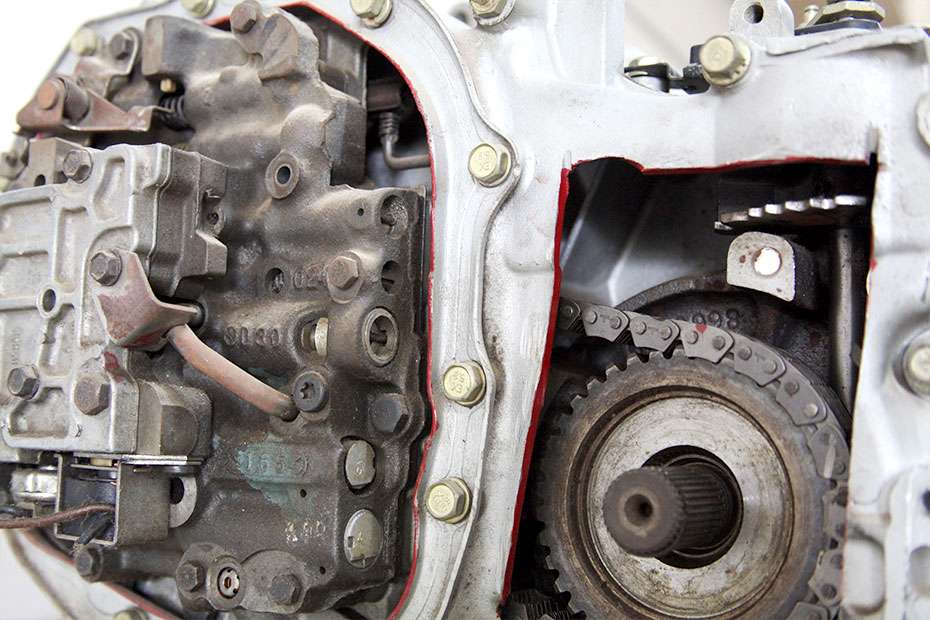

Automobile Engine Lab

With the aim to establish the total understanding of working/studying the parameters/analyzing the heart of an automobile, the engines. The laboratory is equipped with various test rigs (diesel/petrol), exhaust gas analyzer, rope brake dynamo-meter, cut section of entire four wheeler’s and various other modules to perform and study the core of engineering.

The laboratory also is designed to perform various experiments such as engine test rig which can accommodate blends and futuristic alternative fuels.

Vehicle Maintenance and Garage Practice Lab

The aim of department of Automobile Engineering is not only focused on educating students to analyze and design the machines but to teach how to repair/diagnose/replace various components and systems of an automobile.

The laboratory consists of industry oriented repairing/diagnosing set ups such as injector cleaning machine, wheel balancing machine, wheel alignment assembly, required pit and tools for servicing a car and a car to perform various processes. The realization and technique of servicing grooms the aspirants for better.

Automobile Component Design Lab

The Automobile component design laboratory showcases the various components of an automotive the achieve clarity while designing the same component biblically. The design process remains the core subject of the engineering offered. The visible experience enables students to achieve clarity and capability.

Publications

JOURNAL PAPERS

| S.No | NAME OF THE FACULTY | JOURNAL DETAILS | PAPER TITLE | ISSN PUBLISHED YEAR | INTERNATIONAL/ NATIONAL |

|---|---|---|---|---|---|

| 1 | V CHANDRAKALA | INTERNAL JOUNAL ON EMERGING TECHNOLOGIES | INVESTIGATION OF MECHANICAL PROPERTIES OF CHOPPED STRAND E-GLASS FIBER AND BASALT FIBER REINFORCEMENT WITH EPOXY RESIN WITH AND WITHOUT ADDITION OF CRAB SHELL POWDER | 2249-03255 ,2020 | INTERNATIONAL |

| 2 | K JAGADESWARA RAO | INTERNAL JOUNAL OF ALL RESEARCH EDUCATION AND SCIENTIFICE METHODS | DESIGN AND ANALYSIS OF A PASSENGER VEHICLE MULTI- LEAF TANDEM AXLE TRAILER LEAF SPRING | 2455-6211 ,2020 | INTERNATIONAL |

Student Projects

| S.No | PIN NUMBER | STUDENT NAME | BATCH NUMBER | TOPIC |

|---|---|---|---|---|

1 | 14NT1A2401 | A. TRINADH KUMAR | BATCH – 01 | SELF FUEL GENERATING VEHICLE |

2 | 14NT1A2406 | J. HARISH KUMAR | ||

3 | 15NT5A2404 | N. RAVI TEJA | ||

1 | 14NT1A2403 | D. SATISH | BATCH – 2 | PNEUMATIC BIKE |

2 | 14NT1A2409 | P.S.S.M. DEEPAK | ||

3 | 14NT1A2410 | P.LEELA KRISHNA | ||

4 | 15NT5A2401 | B.S.S. PRAKASH | ||

1 | 14NT1A2402 | B. ARAVIND | BATCH – 3 | REDUCING FUEL CONSUMPTION BY ADDING SUITABLE COMPOUNDS |

2 | 14NT1A2404 | G. SUNIL | ||

3 | 15NT5A2402 | G. SATEESH | ||

4 | 15NT5A2405 | R. SHANKAR RAO | ||

1 | 15NT1A2403 | V. ADHEEP | BATCH – 01 | FABRICATION OF FOUR STROKE PETROLE ENGINE FOR IMPROVING FUEL ECONOMY USING WATER INJECTION |

2 | 16NT5A2401 | B.SAIKIRAN | ||

3 | 16NT5A2402 | E.HARSHA | ||

1 | 16NT5A2403 | AVINASH | BATCH – 2 | FABRICATION OF FOUR STROKE PETROLE ENGINE FOR IMPROVING FUEL ECONOMY USING WATER INJECTION |

2 | 16NT5A2404 | VENKATESWARLU | ||

3 | 15NT1A2401 | LUCKY | ||

Intenships

Click here for Internships : Click me

PLACEMENTS

Click here for Placements : Click me

Alumni

| S.NO | NAME | COMPANY | ROLE | PHOTOGRAPH |

|---|---|---|---|---|

1 | B.ARVINDH ( 14NT1A2402) | INFOSYS LIMITED | Systems Engineer |  |

2 | J.HARRISH KUMAR (14NTIA2406) | Fleetronix systems Pvt.Ltd | Operatinos analyst, Hyderabad |  |

3 | K.AKHIL SAI (14NT1A2408) | Thoughtwave Info systems pvt Ltd | Team Lead in US IT Recruiting |  |

4 | K.Yethendra vignesh (19NT5A2406) | KIA | Assembly department |  |